The best oiling system for a race car is a dry sump, simply because it can offer smooth, consistent oil pressure without worry of interruption. However, due to budget constraints or class rules, many racers still depend on a traditional wet sump oil system. Wet sump systems are not only affordable, they consume less horsepower and can be reliable in mild racing applications when the proper system components are chosen.

A wet sump system uses an internal oil pump with a pickup located near the bottom of the oil pan, submerged in oil. Most early model, domestic oil pumps are located in the lower end of the crankcase and are driven off the camshaft, while many late model engines including the GM LS, Ford Modular, and modern Chrysler Hemi have the oil pump mounted to the front of the engine, driven directly off of the crankshaft.

Manufacturers chose to relocate the oil pump to the front of the engine to reduce oil pan depth and increase ground clearance, necessary in today’s low-slung chassis. Unfortunately, a front-mounted oil pump requires an exceptionally long pickup tube, which can expose oil supply problems under extreme racing conditions. This has been a distinct problem when road racing late model LS2- and LS3-powered Corvettes, due to the extreme G-forces reducing oil flow to the pickup. GM addressed this issue by offering the LS7-powered Corvette with an OEM-installed dry sump oil system.

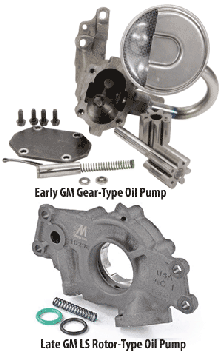

There are two popular types of wet sump oil pumps: gear or rotor style. Gear-type pumps are prevalent in early GM engines, while rotor-style pumps are found on most Ford, Chrysler, and GM LS-series engines. Most pumps consist of a housing equipped with fitted drive and driven gears, a pressure-relief valve or ball, and pressure-relief spring. The oil pump pickup is simply bolted on or pressed into place.

In standard passenger car applications, a wet sump system is more than adequate and relatively trouble-free. When designing a wet sump oil system, the manufacturer calculates the bearing clearances, journal sizes, and other system specifications to determine the engine’s volumetric requirements. They then design an oil pump that typically offers 30% more flow than the engine’s requirements.

In a racing application, however, high engine RPMs and increased G-forces become very detrimental to system operation. According to experts, the crankshaft acts as a windmill within the crankcase, whipping oil up from the sump, while G-forces caused by acceleration, turns, or braking further can impact oil flow to the pickup. This is particularly a problem in road race applications that are subject to left and right turns, hard acceleration and severe braking. It’s under these circumstances that the pickup can become uncovered and ingest air, quickly starving the bearings for oil.

It’s for these reasons that choosing a racing oil pump can help minimize the issues associated with wet sump oiling. Schumann’s Dynamic Performance (available through AFM Performance Equipment) introduced a line of innovative, “Energy Recovery” Pro Series oil pumps that are engineered to help prevent these issues. Company owner Vern Schumann, who has been involved with the refinement of racing oil pumps since 1970, says that the Energy Recovery pump design features a special port that reroutes a small amount of oil from the outlet side of the pump housing into the pump’s inlet tube. This pump design not only “improves oil flow and reduces cavitation at higher pump speeds”, says Schumann, but also “reduces oil starvation risks caused by high G-forces”. As an added bonus, these pumps require less effort to operate, freeing

up a bit of horsepower.

“Energy Recovery” pumps are suitable for racing or street applications and are currently available for small and big block Chevy, small block Ford, GM LS, big block Chrysler and Oldsmobile. All of Schumann’s Chevrolet model pumps utilize upgraded high-strength, iron alloy castings that eliminate the porosity common to standard replacement pumps. Melling, Milodon, and Moroso are additional resources for high-performance racing oil pumps and components.

The remainder of the oil system should also be reviewed and upgraded, if needed. To complete the oil system, consider upgrading to an oil pan designed for the specific type of racing, along with the proper pickup, windage tray, oil restrictors, and a heavy-duty oil pump driveshaft, if applicable. One of the most beneficial factors is keeping the oil level in the sump as far below the crankshaft as possible, which is no simple task given the limited clearances of most low-slung racing chassis. Many engine builders accomplish this by using an oil pan with a built-in pouch or kick-out, which improves oil control by relocating much of the oil down and away from the crankshaft.

Although the old expression “the oil pump is the heart of the engine” remains a valid statement, there are other components in the oil system that are equally important. After all, the best oil pump in the world will do little good unless it is used with corresponding, properly selected system components.